Field Services

In addition to a full service custom machine and fabrication shop, Everett Engineering, Inc. also has complete field machining and welding capabilities. Are field capabilities include, but are not necessarily limited to:

- Small to large turning, facing, and boring

- Line boring

- Portable milling, bed type

- Keycutting

- Drilling

- Precision alignment

- Assembly

- Erection

- Millwrighting

- On-board ship repair

- Troubleshooting

- Equipment installation

Taper Boring

We have several boring bars for turning taper bores (pictured above). We also have a machine for broaching larger taper keyways.

Squirrel Turning

This is the process of turning the end of a shaft in position without having to remove it from your facility.

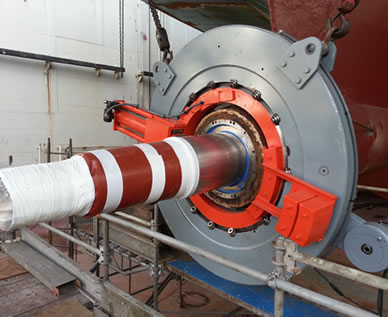

Combination Machining

In this instance we are boring and facing at the same time. This is for the propulsion drive on an aluminum boat. This is another of the machines that we designed and built for a particular application.

Horizontal Facing

Facing can occur in the horizontal or the vertical position. In this picture we are cutting the mounting face for an Azimuth drive in a fire support boat.

Bed Mills

We have several types of bed mills that allow us bring some of the shop milling abilities into the field.

Load Testing

We have calibrated load cells on site ranging from 5000 lbs. up to 150 ton. We also assist in the performance of bollard pull tests for boats requiring ABS certification.

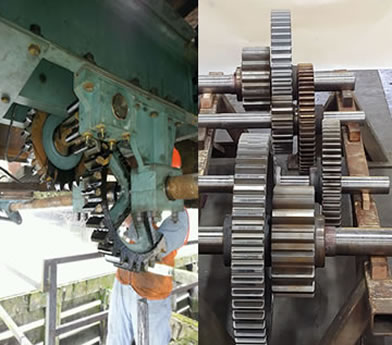

Keyway Machining

Field machining of keyways can be DONE in most positions and be in some hard to get TO locations.

Field Machinery Replacement

Field Welding and Cutting

We have equipment and personnel certified for cutting and welding in the field.

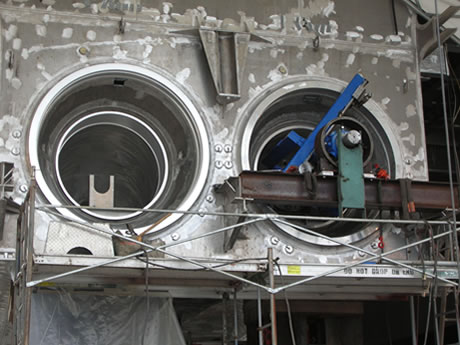

Horizontal Line Boring

Line boring of stern tubes is one of our more common boring jobs. We have bars ranging from 1-1/2″ to 6″ for most line boring applications.

Vertical Boring

Most of our boring bars can be installed in a vertical application, we also have several smaller machines for jobs of a nature where we have limited access.

Horizontal Line Boring

We have several machines that were designed and built for facing purposes such as cutting the face of the stern tube for the installation of a new seal carrier.

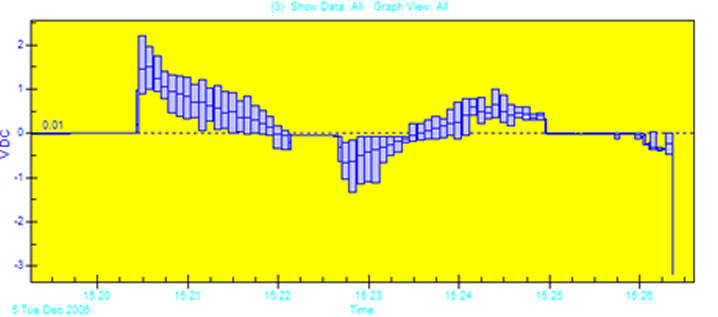

Torsional Shaft Testing

This is data collected from the torsional stress applied to a rotating shaft during the opening and closing of a Bascule type bridge. Testing equipment is applied without any delay in any operation of the bridge and data collected during normal operation through radio signals and no direct connected wires.